565 Blossom Road Rochester,

New York 14610

New York 14610

(585) 482-0044

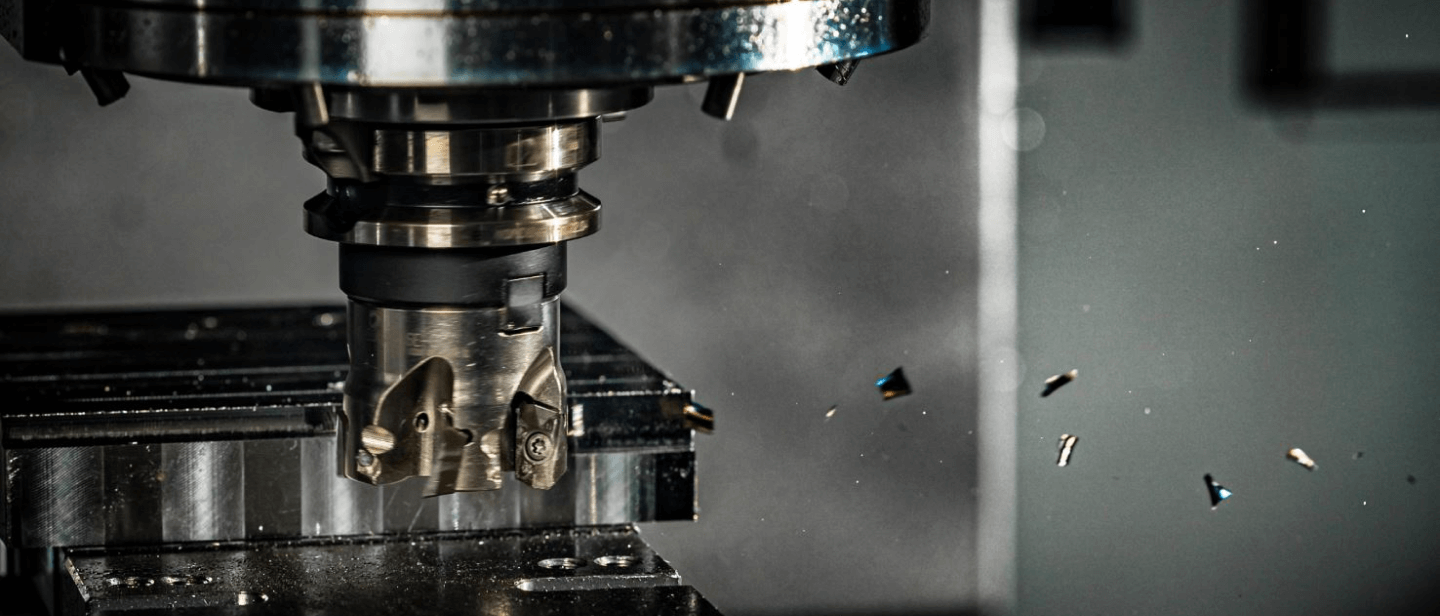

PRODUCTION AND SPECIAL MACHINING, ASSEMBLY SERVICES

SCROLL THROUGH THE LIST OF EQUIPMENT

Zip Products is your source for high quality production, special machining, and assembly services.

We’re your source for CNC proto-type machining, CAD support, high production turning and milling. Conveniently located in Rochester, NY in Western/Central NY state.

OUR CAPABILITIES:

CNC Production machining

Programming done in MASTERCAM

CAD support available for customer parts

Customer Engineering and Design Support

Tool room and mechanical assembly

Production turning and milling

18,000 Sq. Ft. Shop Floor

20+ Employees

QA department with Zeiss CMM

We are experienced in using a variety of materials including stainless/high alloy/hardened steel, aluminum, copper, brass, exotic alloys, castings, forgings, solid stock, and plastics/resins

ISO Certified and ITAR Registered. Cage code 711Y7

FOR MORE INFORMATION ABOUT OUR EQUIPMENT OPPORTUNITIES, SCROLL DOWN BELOW.

• Two 4-Axis Horizontal Machining Center Manufacturing Cell

• 2 levels of 12 500mm Pallets (24 pallet pool)

• 18,000 RPM Spindle Speed

• 2 levels of 12 500mm Pallets (24 pallet pool)

• 18,000 RPM Spindle Speed

• 29” x 29” x 32” Work Envelope

• 280 Tools available within the cell

• Schedule based machining allows for round the clock capacity

• 280 Tools available within the cell

• Schedule based machining allows for round the clock capacity

MAZAK PALLETTECH

• 2-Axis CNC Turning Center

• 2.5” Through Spindle

• 11” Max Turning Diameter

• 2.5” Through Spindle

• 11” Max Turning Diameter

• Bar Feeder

• Parts Catcher

• Parts Catcher

• 4 Axis Vertical Machining Center

• 40 x 20 x 20 Machining capacity

• 7,500 RPM Spindle

• 40 x 20 x 20 Machining capacity

• 7,500 RPM Spindle

• Fadal Programmable Indexing Head

• 21 Tool Magazine

• 21 Tool Magazine

• 4-Axis CNC Turning Center

• Live Tooling

• 3.0” Through Spindle

• 11.4” Max Turning Diameter

• Live Tooling

• 3.0” Through Spindle

• 11.4” Max Turning Diameter

• Programmable Sub-Spindle

• SMW 4 Foot Servo Bar Feeder

• Parts Catcher

• SMW 4 Foot Servo Bar Feeder

• Parts Catcher

• 4-Axis Turning Center with Y-axis

• 2” Through Spindle

• 10.3” Maximum Turning Diameter

• Programmable Tailstock

• 2” Through Spindle

• 10.3” Maximum Turning Diameter

• Programmable Tailstock

• 13.5” Maximum Turning Length

• Milling C-Axis Machining with .0001 deg accuracy plus +/-2.0 for Y-axis

• Automatic Parts Catcher

• ATS 3ft. Servo Bar Feeder

• Milling C-Axis Machining with .0001 deg accuracy plus +/-2.0 for Y-axis

• Automatic Parts Catcher

• ATS 3ft. Servo Bar Feeder

• 5-Axis Turning Center with Y-axis

• 3” Through Spindle

• 11” Maximum Turning Diameter

• 10” Maximum Chucking Diameter

• 16” Maximum Turning Length

• 3” Through Spindle

• 11” Maximum Turning Diameter

• 10” Maximum Chucking Diameter

• 16” Maximum Turning Length

• Milling C-Axis Machining with .0001 deg accuracy plus +/-2.0 for Y-axis

• Sub Spindle for 2nd Process with full C-axis

• Automatic Parts Catcher

• ATS 4ft. Servo Bar Feeder

• Sub Spindle for 2nd Process with full C-axis

• Automatic Parts Catcher

• ATS 4ft. Servo Bar Feeder

• 3-Axis Horizontal Machining Center

• 2 – 400mm Pallet With 800 lb. Capacity And .001 Degree Indexing

• 40 HP 18,000 RPM Spindle Speed

• 2 – 400mm Pallet With 800 lb. Capacity And .001 Degree Indexing

• 40 HP 18,000 RPM Spindle Speed

DAEWOO PUMA 240MS

• 2300 Inches Per Minute Rapid Feed Rate

• 22” x 24” x 25” Work Envelope

• 40 Tool Magazine

• 22” x 24” x 25” Work Envelope

• 40 Tool Magazine

MAZAK QUICK TURN

NEXUS 100IIMY

MAZAK 250/40 MS

• 4-Axis Turning Center

• 3” Through Spindle

• 15” Maximum Turning Diameter

• 10” Maximum Chucking Diameter

• 40” Maximum Turning Length

• 3” Through Spindle

• 15” Maximum Turning Diameter

• 10” Maximum Chucking Diameter

• 40” Maximum Turning Length

• Programmable Tailstock for longer parts

• Milling C-Axis Machining with .0001 deg accuracy plus +/-2.0 for Y-axis

• Automatic Parts Catcher

• ATS 4ft. Servo Bar Feeder

• Milling C-Axis Machining with .0001 deg accuracy plus +/-2.0 for Y-axis

• Automatic Parts Catcher

• ATS 4ft. Servo Bar Feeder

• 8-Axis Swiss Lathe with live tooling

• 1.25" Capacity

• 12 ft automated bar feeder

• 1.25" Capacity

• 12 ft automated bar feeder

MAZAK QUICK TURN

NEXUS 250IIMSY

• Automated parts catcher

• Up to 40 tools

• Up to 40 tools

E-mail: sales@zipproducts.us

CITIZEN CINCOM L32X

565 Blossom Road Rochester,

New York 14610

New York 14610

MAZAK HORIZONTAL CENTER

NEXUS 4000-II

SPECIALISTS IN TURNING AND MACHINING IN ROCHESTER

DAEWOO PUMA 200C

FADAL 4020A VMC